Why T-Shirt Businesses Are Switching

The Rise of DTF Transfer Sheets

In the custom apparel industry, innovation is the driving force behind success. One revolutionary technology, DTF transfer sheets, is transforming how T-shirt businesses operate. These sheets allow businesses to produce high-quality, vibrant designs quickly and affordably. As more entrepreneurs discover their potential, they’re becoming the top choice for maximizing profits. In this guide, we’ll explore why T-shirt businesses are making the switch, the benefits of DTF transfer sheets, and how to implement them effectively in your operations.

1. What Are DTF Transfer Sheets?

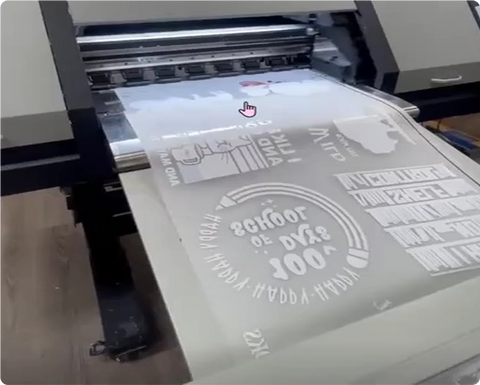

Before explaining their impact, let's define what is meant by DTF transfer sheets. Direct to Film is a modern printing technique that prints designs on a special film; this film is then transferred onto fabric with heat and some adhesive powder.

Key Features:

- Vibrant Colors: These sheets provide unmatched color depth and sharpness.

- Versatility: They work on a variety of fabrics, including cotton, polyester, blends, and even non-textile items like tote bags.

- Durability: Designs made with DTF transfer sheets resist cracking, fading, and peeling.

- Simplicity: No complex setup is required, making the process accessible to small businesses.

2. Why T-Shirt Businesses Are Switching to DTF Transfer Sheets

Cost Efficiency

One of the biggest reasons businesses prefer DTF transfer sheets is the reduction in production costs. Traditional printing methods like screen printing require expensive setup, especially for smaller orders. With DTF, you can print high-quality designs without investing heavily in equipment or materials.

Time Savings

Time is an important factor when it comes to custom apparel production. DTF printing skips tedious steps, such as weeding, which applies to heat transfer vinyl, or making screens, like in screen printing. This makes the process less time-consuming and enables businesses to meet strict deadlines and process more orders.

Exceptional Quality

Today’s customers expect high-quality products. DTF transfer sheets deliver vibrant, precise designs that stand the test of time. The durability of these prints leads to satisfied customers and repeat business.

Versatility Across Fabrics

Unlike sublimation, which can only be performed on light-colored polyester, DTF transfer sheets can be applied to almost any fabric: from dark cotton up to synthetic blends. The flexibility thereby accorded opens opportunities for the creation of more products.

3. Comparing DTF to Other Printing Methods

DTF vs. Screen Printing

- Setup Costs: Screen printing requires creating stencils for each design, making it costly for small or one-off orders. DTF eliminates this need.

- Flexibility: Screen printing struggles with detailed or multicolor designs, while DTF handles intricate artwork with ease.

DTF vs. Heat Transfer Vinyl (HTV)

- Ease of Use: HTV involves cutting and weeding designs, which can be labor-intensive. DTF skips this step entirely.

- Design Freedom: DTF excels with complex, multicolor graphics, whereas HTV is limited by the number of vinyl colors.

DTF vs. Sublimation Printing

- Fabric Compatibility: Sublimation works only on polyester, whereas DTF prints beautifully on cotton, polyester, and blends.

- Color Range: Sublimation struggles on dark fabrics, but DTF retains vibrancy on all colors.

4. How DTF Transfer Sheets Boost Profits

- Lower Overhead Costs

By reducing the need for expensive equipment and materials, DTF transfer sheets lower production costs significantly. This allows businesses to price their products competitively while maintaining healthy profit margins.

- Expand Product Offerings

With DTF, you’re no longer limited to T-shirts. Offer custom prints on hoodies, hats, tote bags, and more. Diversifying your product range can attract a broader audience and increase revenue.

- Accommodate Small Orders

Most traditional printing methods have minimum order quantities due to the high cost of setup. DTF helps businesses to manage orders starting from one piece or small batches economically and assist customers needing their personalized or one-off designs.

- Build Customer Loyalty

High-quality prints ensure satisfied customers who return for more. Plus, the ability to offer unique, personalized items enhances customer loyalty and encourages word-of-mouth referrals.

5. Steps to Incorporate DTF Transfer Sheets into Your Business

Step 1: Invest in Essential Equipment

To use DTF transfer sheets, you’ll need:

- DTF Printer: Designed to print directly onto transfer sheets.

- Heat Press Machine: For transferring designs onto fabric.

- Adhesive Powder: Ensures designs bond securely to the material.

Step 2: Master the Process

Using DTF transfer sheets involves three main steps:

- Print the Design: Create digital artwork and print it onto the transfer sheet.

- Apply Adhesive Powder: Sprinkle adhesive powder over the printed design and cure it.

- Transfer to Fabric: Use a heat press to transfer the design onto your chosen material.

Step 3: Source Quality Materials

High-quality transfer sheets and inks are essential for producing professional results. Low-quality materials may lead to faded prints and dissatisfied customers.

Step 4: Market Your Services

Promote your DTF capabilities online and locally. Highlight their benefits, like quick turnaround times, vivid designs, and versatility, to attract more customers.

6. Real-Life Examples of Success

Startup Growth with DTF

A small custom apparel startup switched from HTV to DTF transfer sheets and noticed a 40% rise in orders within three months. This allowed the company to expand its printing services, offering bright, long-lasting prints on different fabrics to appeal to new customers.

Scaling Established Businesses

A mid-sized T-shirt company used DTF technology to streamline production, reducing labor costs by 20%. By offering bulk discounts on DTF prints, they secured several lucrative contracts.

7. The Future of DTF Transfer Sheets in the T-Shirt Industry

The technology will continue to become even more accessible and efficient. Companies will find a better quality of material, higher speed of printers, and more reasonable prices. By adopting DTF now, your business positions itself as an innovative leader within the custom apparel market.

8. Tips for Maximizing DTF Profitability

- Offer Seasonal Designs: Create themed collections for holidays or events to boost sales.

- Bundle Products: Combine T-shirts with other items like hoodies or tote bags for added value.

- Partner with Local Businesses: Offer branded merchandise printing for local companies to secure steady orders.

The DTF Advantage for T-Shirt Businesses

Switching over to DTF transfer sheets is more than just moving up a notch in technology; it's a strategic move in increasing profits, simplifying operations, and responding to customer demands. Their affordability, versatility, and quality make them a very viable solution for T-shirt businesses of any size. With the incorporation of DTF technology, one will be able to stay competitive, expand the product range, and attract a loyal customer base. Happy Printing!