In the fast-changing world of custom printing, new technologies are constantly redefining the manner in which businesses and individuals realize their creative vision. Two of the processes that are extremely popular nowadays are UV DTF (Ultraviolet Direct-to-Film) and DTF (Direct-to-Film) printing.

At first glance, these two types of printing are similar — they are both using transfer films and are capable of producing professional-grade output — but in reality, they are utilized for applications that are quite distinct. Whether you are producing custom t-shirts, bottles, mugs, signs, or labels, understanding the difference between UV DTF and DTF printing will help you decide which process you can use for your project.

In this tutorial, we will detail all that you need to know about both methods, contrast their specifications, discuss the strengths and limitations, and help you decide which one is the best choice for your situation.

What Is DTF Printing?

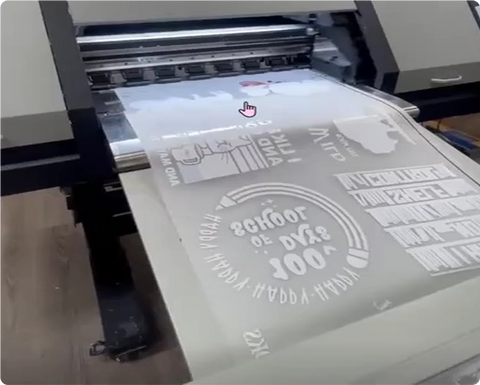

DTF (Direct-to-Film) printing is one of the most innovative and versatile fabric printing technologies available today. Instead of printing directly on a garment (like DTG printing), DTF involves printing your design onto a special PET film using pigment-based inks.

DTF (Direct-to-Film) printing is one of the most innovative and versatile fabric printing technologies available today. Instead of printing directly on a garment (like DTG printing), DTF involves printing your design onto a special PET film using pigment-based inks.

Once printed, a hot-melt adhesive powder is applied to the design. After curing, the film is ready to be heat-pressed onto a fabric surface, creating a long-lasting, colorful, and stretchable print.

How the DTF Process Works

-

Design Creation – The design is prepared digitally in CMYK color format.

-

Film Printing – The design is printed upon PET film utilizing DTF inks (involving a white ink underbase).

-

Adhesive Powder Application – A loose adhesive powder is sprinkled over the printed film to create bonding strength.

-

Curing – The film is heated so that the adhesive powder is melted, preparing it for transfer.

-

Heat Transfer – The film is applied on to material using a heat press machine.

-

Peel and Finish – After cooling, the film is stripped off leaving the image adhered on permanently.

Advantages of DTF Printing

-

Accepts almost any fabric (cotton, polyester, blends, leather, etc.)

-

Produces vibrant colors with soft touch and high stretchability

-

No pretreatment required like DTG printing

-

Suitable for light and dark material

-

High wash resistance and flexibility

Best Uses for DTF Printing

-

Custom t-shirts and hoodies

-

Uniforms and athletic equipment

-

Tote bags and fabric accessories

-

Promotional materials and company-specific apparel

What Is UV DTF Printing?

UV DTF printing, nonetheless, takes print technology to a whole new level. Rather than pigment-based ink, it uses UV-curable ink — these inks are hardened (or "cured") instantly with ultraviolet light during printing.

The result is a raised, textured, and shiny finish that may be impressed into hard, non-porous substrates such as glass, metal, wood, acrylic, and plastic.

Unlike DTF, UV DTF is not a heat press process. The printed artwork is deposited via a peel-and-stick adhesive process, hence a clean and efficient means of printing.

How the UV DTF Process Works

-

Design Preparation – The digital artwork is prepared and designed for printing.

-

Printing – The UV printer lays down layer by layer the design in CMYK and white inks, and varnish for gloss or texture.

-

UV Curing – While being printed, the UV lights immediately cure the ink, creating a solid and embossed design.

-

Transfer Application – The printed film (A film) is combined with an adhesive transfer sheet (B film).

-

Peel and Stick – The design is peeled off and sticks to the surface — no heat or pressure required.

Advantages of UV DTF Printing

-

Can be printed onto any hard surface (glass, metal, wood, ceramics, plastic, acrylic)

-

Holds 3D, glossy, and embossed finishes

-

Very tough, water-resistant, and scratch-resistant

-

No heat press or waiting time when printing

-

Works best for small businesses and promotions

Best Applications for UV DTF Printing

-

Customized tumblers, mugs, and bottles

-

Phone cases and electronic accessories

-

Product stickers and brand labels

-

Signage and home decor

UV DTF vs DTF: Comprehensive Comparison

To better comprehend the difference between these two processes, let's compare them side by side:

| Feature | DTF Printing | UV DTF Printing |

|---|---|---|

| Ink Type | Pigment-based inks | UV-curable inks |

| Curing Method | Heat press | UV light |

| Transfer Method | Heat transfer | Peel and stick |

| Surface Compatibility | Fabrics | Hard surfaces |

| Finish | Soft, matte, flexible | Glossy, raised, textured |

| Durability | Excellent on textiles | Superior on non-porous materials |

| Touch & Feel | Smooth and soft | Hard, embossed texture |

| Color Vibrancy | Bright and accurate | Glossy and vivid |

| Required Equipment | DTF printer, powder shaker, heat press | UV printer, laminator |

| Production Cost | Lower | Slightly higher |

| Ideal Applications | Apparel, bags, fabrics | Tumblers, mugs, signs, bottles |

Pros and Cons of Each Method

DTF Printing Advantages

- Can be used on most fabric types

- Flexible, washable, and durable

- Cost-effective for clothing print

- Soft touch finish on apparel

DTF Printing Disadvantages

- Only effective on fabrics and soft products

- Requires a heat press and curing process

- Not ideal on glossy or hard surfaces

UV DTF Printing Advantages

- Works on nearly all solid surfaces

- Stunning 3D glossy finish

- UV, water, and scratch-resistant

- No need for heat press

UV DTF Printing Cons

- Slightly more expensive in terms of material and equipment cost

- Not possible to use fabric

- Requires precise handling while transferring

Which Printing Method Should You Choose?

It completely depends on the material of print and where it has to be placed whether you should choose DTF or UV DTF.

-

If your business is custom apparel and you would like to print on shirts, hoodies, or uniforms, then DTF printing is your go-to choice.

-

If you want to print on hard goods like tumblers, bottles, or business gifts, UV DTF offers unbeatable durability and looks.

DTF Print DC has both printing methods under one roof, and therefore you can be certain to get the best possible print quality for your project type.

Whether for event custom t-shirts or corporate tumblers in your company, our experts will help you choose the most appropriate and affordable printing method.

Misconceptions About UV DTF and DTF

Myth 1: UV DTF and DTF use the same printer

Not true — they require entirely different machines, inks, and curing. UV printers cure ink with light, while DTF printers cure inks and adhesive powder with heat.

Myth 2: UV DTF can be used on fabrics

UV DTF adhesives do not adhere well to soft, porous surfaces. The print would peel off immediately. Use only DTF or DTG for fabrics.

Myth 3: DTF prints fade quickly

High-quality DTF prints are extremely durable and can survive dozens of wash cycles without cracking or fading when applied appropriately.

Practical Applications for Businesses

DTF printing and UV DTF both unlock hundreds of possibilities for small businesses, creators, and entrepreneurs.

-

For fashion brands: DTF printing allows on-demand rapid customizing of clothing without the inconvenience of screen setup.

-

For gift shops: UV DTF is well-suited to personalizing mugs, bottles, ornaments, and keepsakes.

-

For promotional marketing: UV DTF is capable of producing professional labels, logos, and stickers with great finishes that grab attention.

If you're running an Etsy shop, promotional products company, or local brand, these technologies allow you to offer high-quality, custom products at reasonable costs.

FAQs About UV DTF and DTF Printing

1. Can UV DTF be used on t-shirts or fabric?

No. UV DTF is only for hard surfaces. On clothes or fabrics, try DTF printing instead.

2. Is DTF printing better than UV DTF?

Neither is "better" — it simply depends on your use. DTF is wonderful for fabrics, and UV DTF is wonderful for hard surfaces.

3. Which printing method lasts longer?

Both are very durable. UV DTF will outlast on hard surfaces because it is UV-curable ink and scratch- and water-proof.

4. Must I use some specialty piece of equipment to do work with UV DTF transfers?

No heat press is required. You peel and apply the transfer onto your surface.

Where to Get Professional DTF Printing

At DTF Print DC, we combine advanced technology with creative expertise to deliver stunning, durable, and vibrant custom prints for every project.

Whether you need:

-

Custom apparel printing using DTF

-

Same-day DTF prints

-

Or nationwide shipping for bulk orders

—we’ve got you covered.

Our team is dedicated to ensuring your designs stand out with precision, color accuracy, and quality you can feel.

Final Thoughts

In summary, both UV DTF and DTF printing represent the future of custom printing — each offering unique advantages for different materials and applications.

If your goal is to create soft, flexible, and colorful designs on clothing, DTF printing is your go-to choice. If you want sleek, durable, and glossy finishes on hard surfaces, UV DTF printing is unmatched in quality and longevity.

At DTF Print DC, we make it easy to get the best of both worlds. From t-shirts to tumblers, our advanced printing solutions help your brand, business, or event shine in every detail.