Why Small Businesses Should Embrace DTF Transfers for Branding and Products

In the sphere of branding and creating merchandise for your small business, the right transfer method can make quite a difference. DTF transfers ready to press are swiftly emerging as a major toolkit for businesses intent on producing high-quality, value-added apparel, promotional products, and merchandise.

In this post, we’ll explore five reasons why DTF transfers ready to press are perfect for small business branding and merchandise production. From cost-effectiveness to ease of use, DTF transfers offer several advantages that make them an excellent choice for small business owners.

What Are DTF Transfers Ready to Press?

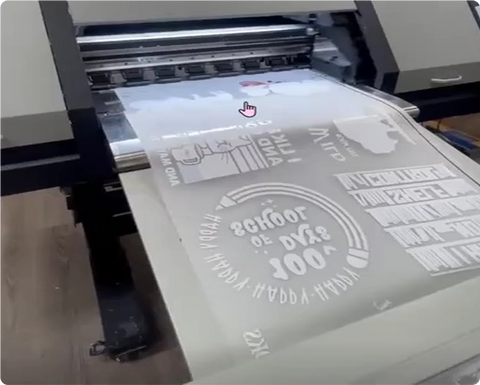

DTF transfers ready to press refer to prints that are prepared using the Direct-to-Film (DTF) method, then pre-printed and coated with adhesive powder, ready to be transferred onto fabric with a heat press.

The transfer film is printed with your design, and the adhesive is applied in such a manner that, once heat is applied, vibrant and high-quality results are achieved. The "ready to press" part means pre-prepared transfers; therefore, there are no difficult setups or time-consuming processes involved, which is a major plus for small businesses.

1. Cost-Effective for Small Businesses

One of the biggest benefits of DTF transfers ready to press is the affordability they provide. For small businesses, keeping costs down while maintaining quality products is paramount. Traditional options, such as screen printing or embroidery, can be very expensive in setup costs alone, especially with small orders.

DTF transfers ready to press avoid expensive machinery and can be quickly produced with low labor, making them much more affordable for a small-scale production. Moreover, DTF transfers ready to press also do not require any special knowledge or extensive experience.

The process is quite straightforward, meaning small business owners or their staff can be taught how to operate the equipment and start producing personalized items in no time, without prior extensive training or investing in expensive machinery.

In our Best DTF Printer for Small Business: Top Picks and Buying Guide blog, you can reach more information about DTF printers.

2. Versatility in Design and Fabric Choices

Small businesses often have to cater to many customers by offering a wide variety of products, and the DTF transfers ready to press are extremely versatile. This transfer method enables you to print full-color, intricate designs onto a range of fabrics, from pure cotton to pure polyester and even blends. Be it customized t-shirts, hoodies, hats, or tote bags, DTF transfers can easily be applied to almost any kind of fabric.

With DTF transfers ready to press, the designs you will be able to create can also feature bright colors, gradients, and fine details, which are perfect for custom branding or making customized merchandise that stands out.

Unlike traditional methods such as screen printing, which can often be very restricted in color complexity, DTF transfers have absolutely no issue handling multiple colors and gradient changes, allowing you to deliver more creative and detailed designs to your customers.

3. Quick Turnaround Times for Orders

In today's world of speedy business, customers expect quick turnarounds. When fulfilling orders for anything from custom apparel to branded merchandise, DTF transfers ready to press can help even a small business meet those expectations. Once the transfer is pre-printed and ready, applying it to the garment takes very little time. This makes DTF transfers an ideal choice for businesses that need to deliver on-demand, fast turnaround products.

Whether you are producing one-off custom items or a small batch, DTF transfers ready to press speed up the process because they can be quickly pressed onto fabric. This is particularly beneficial for small businesses that rely on quick fulfillment to meet customer demands, seasonal trends, or special events.

4. High-Quality, Durable Prints

Durability is a key factor when it comes to custom apparel and merchandise. No business wants to invest in a printing method that leads to designs fading or cracking after just a few washes. DTF transfers ready to press provide a durable solution for long-lasting prints. The design adheres securely to the fabric, ensuring that it remains vibrant and intact even after multiple washes.

Unlike other transfer methods, which may result in peeling or cracking of the design over time, DTF transfers are of higher quality and long-lasting. Thus, let your small business deliver high-quality, lasting products to enhance your brand's reputation in the market concerning quality and reliability.

5. Minimal Waste and Environmental Impact

Besides the financial benefits, waste reduction is generally a responsible business practice for small businesses. DTF transfers ready to press enable companies to print only what is needed, thus reducing the excess inventory or waste from their production, as with other printing techniques. The DTF transfer prints the design directly onto the fabric without any major losses of materials.

This is also a somewhat greener technology, since DTF transfers ready to press are associated with far less waste than other printing techniques, such as screen printing, which generally require huge volumes of water and chemicals during the processing.

This makes DTF transfers a more viable alternative for small businesses that want to reduce their ecological footprint, due to the possibility of producing smaller runs of merchandise without generating much waste.

How to Use DTF Transfers Ready to Press

Now that you understand the advantages of DTF transfers ready to press, let’s take a look at how to apply these transfers effectively to your merchandise. The process is relatively straightforward and involves a few key steps.

- Prepare the Design: First, create or upload the design that you want to use for your custom products. Ensure that it’s formatted correctly for DTF transfers ready to press.

- Print the Design: Use a compatible printer to print your design onto special DTF film. The design will be printed in reverse, so be sure to mirror the image before printing.

- Apply the Adhesive: Once the design is printed, apply a layer of adhesive powder to the wet ink. This powder will help bond the design to the fabric when heat is applied.

- Cure the Transfer: The printed film must be cured to activate the adhesive powder. This can be done with a curing oven or heat press.

- Press the Transfer: Once the transfer is ready, position it on the garment and apply heat and pressure with a heat press for a specified amount of time.

- Peel and Inspect: After pressing, carefully peel off the transfer film and inspect the design to ensure it has adhered properly to the fabric.

Tips for Getting the Best Results with DTF Transfers Ready to Press

To ensure the best results, here are a few tips to keep in mind when using DTF transfers ready to press:

- Use the Right Heat Settings: Be sure to use the recommended temperature and pressure settings for the particular transfer film and fabric being used to avoid damaging the design or the garment.

- Preheat Your Garment: It opens up the fabric, removing any moisture, hence allowing better adhesion and smooth application.

- Test the Process: Before applying DTF transfers ready to press on a large batch of items, do a test to make sure settings and the transfer process are optimized with your materials.

Why DTF Transfers Ready to Press Are Perfect for Small Business Branding and Merchandise

The ready-to-press DTF transfers are practical, cost-effective, and qualitative, suitable for small businesses in the production of value-added apparel and merchandise. Be it custom branded tees, hoodies, or promotional items, DTF transfers offer a simple and quick way to produce professional-grade products.

The versatility of the design, speed of turnaround, and durability in prints make transfers an ideal solution to help small business owners expand their brand and offer merchandise that is unique to their customers. It is proper to provide high-quality and custom products to amaze your target market or client by using DTF transfers ready to press.