How to Select the Best Transfer Method for Your Clothing Projects

So, you're looking to put your awesome designs onto fabric, right? Well, you've come to the right place! There are tons of ways to do that, but one of the coolest and most popular methods is DTF heat transfers. They're like super-powered stickers that you can use to customize t-shirts, hoodies, bags, and so much more.

But hold on! Before we dive into the amazing world of DTF, let's talk about why choosing the right transfer method is so important. Think of it like choosing the right paint for a masterpiece.

The right method can make your design pop, last longer, and feel comfy on your clothes. Whether you're starting a t-shirt business, making custom hoodies for your friends, or just want to add some flair to your own wardrobe, picking the right way to transfer your design is key!

In this guide, we'll be your DTF experts, breaking down everything you need to know about this awesome technique. We'll explore how it works, compare it to other methods out there, and help you figure out if it's the right choice for your awesome projects. Get ready to unlock a whole new level of customization!

What Are DTF Heat Transfers?

DTF (Direct-to-Film) heat transfers are like a super cool, high-tech version of those iron-on transfers you might have used as a kid! It's a pretty new method for getting your designs onto fabric, and it's quickly becoming a favorite for all sorts of creative projects.

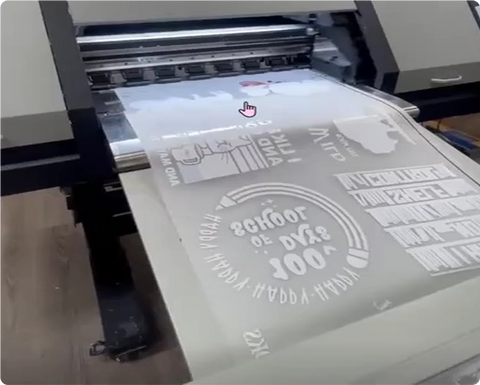

Here's the basic idea: you print your design onto a special film using a DTF printer (kind of like a regular printer, but specifically for this purpose). Then, you use a heat press (like a giant iron) to transfer that design from the film onto your t-shirt, hoodie, or whatever you're customizing.

What's so great about DTF? Well, for starters, the colors are incredibly vibrant and the details are super sharp. Plus, it's way more durable than older methods like screen printing or vinyl transfers. Your designs will last wash after wash without cracking or fading. And because the print goes directly from the film onto the fabric, the final result looks super professional and crisp.

Why Choose DTF Heat Transfers for Your Apparel?

One of the coolest things about DTF heat transfers is how versatile they are. They're like the superheroes of the fabric world! Here's why:

- Fabric freedom: DTF works on all sorts of fabrics, from cotton and polyester to blends. This means you can customize t-shirts, hoodies, hats, bags, and so much more!

- Soft and comfy: The prints you get with DTF are super soft to the touch. You won't feel any thick or stiff patches on your clothes like you might with some other transfer methods.

- Color explosion: DTF lets you create full-color designs with tons of detail. So, if you've got a complex image or artwork you want to transfer, DTF can handle it!

But wait, there's more! Here are some other awesome benefits of DTF heat transfers:

- Super durable: DTF prints are tough cookies. They're designed to last through lots of washes without fading or cracking. Your designs will stay looking awesome for ages!

- Eye-popping colors: The colors in DTF heat transfers are seriously vibrant. They'll make your designs pop and grab everyone's attention.

- Easy on the wallet: Compared to other methods like screen printing, DTF can be more affordable, especially if you're just starting out or need a small batch of custom items.

- No fuss, no muss: Unlike some other printing methods, DTF doesn't require any special pre-treatment of the fabric. This makes the whole process simpler and faster.

With all these amazing benefits, it's no wonder DTF heat transfers are becoming so popular!

DTF Heat Transfers vs. Other Transfer Methods

When deciding on the best transfer method for your apparel, it's important to compare DTF heat transfers to other popular options like screen printing, sublimation, and heat press vinyl. Each method has its own strengths and limitations.

Screen Printing vs. DTF Heat Transfers

You're right! Screen printing has been the king of custom apparel for a long time. It's like the old reliable method that everyone knows. Basically, it involves creating stencils (called screens) and using ink to push the design onto the fabric.

Screen printing works great if you need a ton of shirts with a simple design, but it has some downsides, especially if you want something detailed or colorful. Imagine trying to create a super intricate design with lots of colors using stencils – it would be pretty tricky!

That's where DTF heat transfers come in to save the day! DTF can handle those full-color images with fine details and gradients without breaking a sweat. It's like the superhero of detailed designs!

Another cool thing about DTF is that it's way more accessible than screen printing. You don't need a bunch of fancy equipment or a huge workshop. You can create DTF transfers with a regular inkjet printer, which makes it perfect for small businesses, individuals, or anyone who wants to create awesome custom apparel without a huge investment.

Sublimation Printing vs. DTF Heat Transfers

Sublimation printing is another cool way to get designs onto fabric. It's like magic! You use special inks that turn into a gas when heated, and that gas permanently dyes the fabric. It works amazingly on polyester and creates super bright, long-lasting prints.

But here's the catch: sublimation printing only works on light-colored fabrics. Why? Because the inks are kind of see-through. Imagine trying to color a black piece of paper with a yellow marker – you wouldn't see it, right?

That's where DTF heat transfers have the upper hand! DTF works on both light and dark fabrics, so you have way more freedom to choose the colors and styles you want. It's like having a universal design tool for your clothes!

Heat Press Vinyl vs. DTF Heat Transfers

Heat press vinyl (also known as HTV) is kind of like creating a sticker for your clothes! You cut out your design from a sheet of vinyl and then use a heat press to stick it onto the fabric. It's great for simple designs and bold logos, but it can get a bit tricky when you want to create something more complex with lots of colors.

Imagine trying to create a realistic portrait or a design with lots of tiny details using HTV – it would be like putting together a puzzle with hundreds of tiny pieces!

DTF heat transfers, on the other hand, are perfect for those intricate designs with gradients and a full spectrum of colors. Think of it like printing a high-quality photo directly onto your clothes! This makes DTF a much better option for detailed artwork, complex designs, and anything that requires a wide range of colors.

Plastisol Transfers

Plastisol transfers give you really strong and vibrant prints. These transfers are like the tough guys of the custom apparel world, they can handle tons of washes and still look amazing. You can print a bunch of them and keep them stored away for whenever you need them, which is super handy. The one thing to keep in mind is that they can feel a bit heavy on the fabric, so they might not be the best for lightweight clothes or hot summer days. Also, they're not super stretchy, so they might not be ideal for fabrics like spandex.

Water-Based Transfers

If you want a design that feels like it's part of the fabric, water-based transfers are the way to go. They're super soft and comfy against your skin. Plus, they use eco-friendly inks, so you can feel good about your impact on the planet. Another cool thing is that they let the fabric breathe, so your clothes will be more comfy to wear. One thing to keep in mind is that they're not quite as tough as plastisol transfers, so they might not be the best for clothes you wash a lot. Also, they work best on light-colored fabrics since the inks are a bit see-through.

Factors to Consider When Choosing DTF Heat Transfers

Okay, so you're convinced that DTF heat transfers are pretty awesome, right? But before you jump in headfirst, there are a few things to consider to make sure it's the perfect fit for your project. It's like choosing the right tool for the job!

Fabric type: First things first, what kind of fabric are you working with? DTF is super versatile and works on most fabrics, including cotton, polyester, and blends. This makes it a great option for customizing a wide range of apparel, from t-shirts and hoodies to hats and bags.

Design complexity: Is your design a simple logo or a super detailed masterpiece? DTF heat transfers are the champions of intricate designs, gradients, and a wide range of colors. If you want your design to look sharp and professional with all its fine details, DTF is the way to go.

Order size: How many items are you customizing? DTF is a great choice for small or medium-sized orders because it doesn't require a lot of setup time like screen printing. This makes it perfect for custom orders, one-off creations, or small batches of personalized apparel. However, if you're planning on making hundreds of shirts with a simple design, screen printing might be more cost-effective in the long run.

Budget: Of course, budget is always a factor! DTF heat transfers tend to be more budget-friendly for smaller orders, but for larger projects with simpler designs, screen printing might be the more economical choice. It's always a good idea to compare costs and see what works best for your specific needs.

To help you make the best decision, you can check out our blog post comparing DTF transfers and traditional screen printing: [insert blog post link here - you'll need to provide this]. It's got tons of helpful info to guide you through the decision-making process.

How to Apply DTF Heat Transfers: A Step-by-Step Guide

So you've decided to go with DTF heat transfers? Awesome! Now, let's walk through how to actually apply these awesome transfers to your clothes. It's like following a recipe for amazing custom apparel!

1. Get your design ready: First things first, you need a design! Create your own masterpiece or choose one you love. Just make sure it's formatted correctly for DTF printing.

2. Print it out: Now, use a special inkjet printer (made for DTF printing) to print your design onto the transfer film. Important tip: print the image in reverse (like looking in a mirror) because you'll be applying it face down on the fabric.

3. Add the magic powder: While the ink is still wet, sprinkle a special adhesive powder over your design. This powder is like the secret ingredient that makes your design stick to the fabric during the transfer process.

4. Melt the magic: Next, you'll need to cure the design. This means using a heat press or a special curing oven to melt the adhesive powder and bond the print to the transfer film. Think of it like melting cheese onto a pizza – it makes everything stick together nicely!

5. Transfer time: Now, carefully place the transfer film onto your garment with the design facing down. Use your heat press to apply heat and pressure, which will transfer the design from the film to the fabric. It's like a super-powered iron-on!

6. The big reveal: Once the transfer is complete, carefully peel off the film. Ta-da! Your awesome design should now be perfectly printed on your garment. Inspect it closely to make sure everything looks good.

And there you have it! You've officially mastered the art of applying DTF heat transfers. Now go out there and create some amazing custom apparel!

Best Practices for Long-Lasting DTF Heat Transfers

You're well on your way to becoming a DTF pro! Here are a few extra tips to help you achieve the best possible results and make your designs last:

- Warm it up: Before you apply your DTF transfer, give the fabric a quick preheat with your heat press or iron. This will help get rid of any moisture and wrinkles, creating a smooth surface for your design to stick to.

- Follow the instructions: Every DTF transfer has its own recommended temperature and pressure settings. It's super important to follow these guidelines to avoid damaging the transfer or the garment. Think of it like baking a cake – you need to follow the recipe to get the best results!

- Wash with care: To keep your designs looking their best, turn your garment inside out before washing it. This helps protect the print from rubbing against other clothes in the washing machine. Also, avoid using bleach or harsh detergents, as these can fade or damage the design.

With these tips and a little practice, your DTF heat transfers will look amazing and last for a long time!

Why DTF Heat Transfers Are the Best Choice for Your Apparel Needs

Choosing the right way to transfer your designs onto fabric is like picking the perfect pair of shoes – it needs to fit your needs and style! DTF heat transfers are a fantastic option because they offer a great balance of quality, versatility, and affordability.

They're like the all-around champions of customization, able to handle detailed designs in full color and work on all sorts of fabrics. This makes them a fantastic choice for businesses and individuals who want to create unique, professional-looking custom apparel.

By following the simple steps and tips we've shared in this guide, you'll be a DTF master in no time! You'll be creating amazing, long-lasting designs that will wow everyone.

So, what are you waiting for? Unleash your creativity and start printing! Happy crafting!