DTF Regular Iron: Your Gateway to Affordable Garment Printing

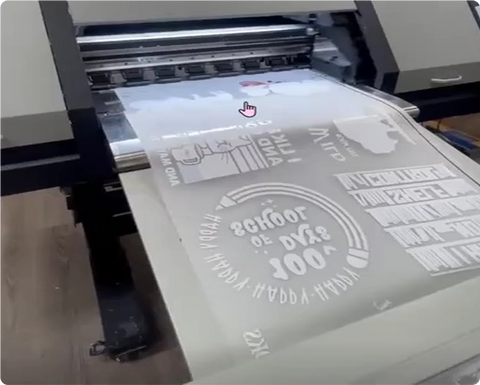

Ever heard of DTF printing? It's seriously changing the game for custom clothes! Basically, it's a super cool way to print awesome designs onto all kinds of fabrics. Now, I know what you're thinking: "DTF printers? Heat presses? That sounds expensive!" But guess what? You can actually get amazing results with just a regular iron – the kind you probably already have at home!

Yep, you heard that right! This guide is all about DTF printing with a regular iron. We'll break down everything you need to know, from how to use it to what to look for when you're buying one. Plus, we've got tons of insider tips to help you get those prints looking top-notch. So grab your iron, and let's get craft!

What Exactly is a DTF Regular Iron?

So, you're curious about DTF printing with a regular iron? It's actually pretty simple! Basically, it's like using your everyday iron, but instead of just getting wrinkles out of your clothes, you're using it to stick awesome designs onto them.

Now, you might be thinking, "Wait, isn't there fancy equipment for that?" You're right, there are these things called heat presses, but they can be pricey. A regular iron does the trick too, and it's way easier on the wallet!

Think of it as a more hands-on approach. You're in control of the heat and pressure, which makes it perfect for smaller projects or if you're just starting out. And don't worry, you can still get amazing, long-lasting prints that look just as good as those made with expensive machines. It's all about getting the technique down!

Why Choose a DTF Regular Iron?

-

Cost-Effective Printing: Okay, let's talk about the elephant in the room: money! Those fancy heat press machines? They can cost a pretty penny. We're talking hundreds, even thousands of dollars! Ouch, right?

That's where your trusty regular iron comes in. It's like the superhero of budget-friendly DTF printing! You can snag a good one for a fraction of the price of a heat press, which is a total game-changer if you're just starting out or running a small business from home. Who needs to break the bank when you can get awesome results with something you probably already have?

-

Compact and Portable: Let picture this: those big, clunky heat press machines? They're like the hulking SUVs of the crafting world. They take up tons of space, weigh a ton, and aren't exactly easy to move around.

Now, imagine a sleek, compact sports car. That's your regular iron! It's small, lightweight, and easy to stash away when you're not using it. Perfect if you're short on space or like to take your crafting on the go. No need to lug around a giant machine – just toss your iron in a bag and you're good to go.

-

Simplicity and Convenience: Using a DTF regular iron is straightforward. With just a few adjustments to the temperature settings and pressure, you can transfer designs onto fabrics. This simplicity makes it an excellent choice for beginners or those who want to avoid the complexities of a heat press machine.

Choosing the Right Iron for DTF Magic: Essential Features

Not all irons are created equal, especially when it comes to the delicate art of DTF transfers. To achieve those vibrant, long-lasting results you're after, it's essential to choose an iron with the right features. Here's what to look for:

1. Temperature Control: Your Iron's Secret Weapon

So your iron isn't just for wrinkles anymore. Think of it like a chef's knife – a precision tool for your DTF creations!

Just like different foods need different cooking temps (you wouldn't bake a cake at the same heat as you sear a steak, right?), different fabrics and transfer films have their own sweet spot when it comes to heat. Too hot, and you could scorch your fabric or ruin your design. Too cold, and it won't stick properly.

That's why it's super important to have an iron with adjustable temperature settings. It lets you fine-tune the heat to get it just right, like Goldilocks finding the perfect porridge! Always check the instructions that come with your DTF film, though. They usually have a handy guide for the ideal temperature range for different fabrics.

2. Even Heat Distribution: The Key to Flawless Transfers

Imagine trying to toast a marshmallow with a lighter – you'll end up with some parts burnt and others raw. The same principle applies heat to DTF transfers. An iron with uneven heat distribution can lead to patchy transfers, with some areas sticking properly and others peeling or fading.

To avoid this, look for an iron with a flat soleplate (the bottom part that touches the fabric). A ceramic or non-stick soleplate is ideal, as it ensures the heat is spread evenly across the surface, eliminating those pesky hot spots that can ruin your design.

3. Steam Power: A Wrinkle-Busting Superhero (Sometimes)

Now, about that steam button on your iron... it's like a secret weapon for prepping your clothes! A quick shot of steam can work wonders for getting rid of wrinkles and making sure your fabric is perfectly smooth before you apply your transfer. Think of it as giving your garment a mini spa treatment!

But here's the catch: make sure you turn off the steam when you're actually pressing the transfer onto the fabric. Too much moisture is like kryptonite for that DTF adhesive. It's like trying to stick a sticker on a wet surface – no chance it's going to hold! So, steam for prep, no steam for the main event. Got it?

How to Use a DTF Regular Iron: Step-by-Step Guide

If you’re new to DTF printing or using a DTF regular iron, here’s a simple, step-by-step guide to help you achieve the best results:

1. Prepare the Garment

First of all, ensure that your garment is clean and has no wrinkles. Use either a steamer or a steam function on your iron to remove the wrinkles of the garment before applying a DTF transfer film, so your design will perfectly adhere to the fabric.

2. Preheat the Iron

Set your iron to the appropriate temperature for the DTF film you’re using. Most DTF transfer films require a temperature of around 320°F (160°C), but it’s important to check the specific temperature recommendation for the film you have. Allow the iron to heat up to the desired temperature before starting.

3. Position the Transfer Film

Place your printed DTF film on the fabric in the right position. You can put a sheet of parchment paper or Teflon between the transfer and the fabric to prevent them from touching the iron directly; this will also prevent the film from sticking to the soleplate.

4. Apply the Iron

Once the transfer is in place, apply firm, consistent pressure with the DTF regular iron. You may have to move the iron slightly to cover the whole design, making sure it has an even spread of heat. Hold the iron in place for about 20-30 seconds, varying with film and fabric type.

5. Cool Down and Peel

After pressing, allow the transfer to cool for a few seconds before slowly peeling the film off the apparel. Be sure and let the transfer cool completely so the print will bond appropriately.

Common Mistakes to Avoid When Using a DTF Regular Iron

To achieve the best results with a DTF regular iron, avoid the following common mistakes:

1. Using Too Low or Too High a Temperature

Using incorrect temperature settings is one of the most common mistakes when working with a DTF regular iron. If the temperature is too low, the design may not adhere properly, while too much heat can cause the fabric to scorch or the design to fade.

2. Insufficient Pressure

Alright, listen up! This is super important: when you're using your iron for DTF transfers, pressure is key. Think of it like giving your design a big, warm hug!

If you're too gentle with the iron, your design might not stick properly. It's like trying to put a puzzle together without pressing the pieces firmly into place.

So, when you're ironing that transfer on, make sure you press down nice and firm. And keep that pressure even across the whole design, so it sticks perfectly everywhere. No wimpy presses allowed!

3. Rushing the Process

I know, I know, you're excited to see your awesome design on your shirt! But trust me, when it comes to DTF transfers, patience is your best friend. Think of it like baking a cake – you can't rush the oven, or you'll end up with a gooey mess. Same goes for your DTF transfers.

Make sure you give that iron enough time to work its magic and transfer the whole design. And once you're done pressing, let it cool down completely before you peel off the film. Think of it as letting the glue set. Rushing things will only lead to disappointment, so take a deep breath, relax, and enjoy the process!

Level Up Your DTF Iron Game: Extra Tips for Transfer Triumph

Want to become a true DTF iron master? Here are some extra tips to help you achieve those jaw-dropping, long-lasting transfers:

1. Film Choice: Not All Films Are Created Equal

Think of DTF transfers films like different types of paint. Some are perfect for intricate details, others excel at bold, vibrant colors, and some are specifically designed for certain fabrics. Just like you wouldn't use watercolor paint on a canvas meant for oils, you need to choose the right DTF film for the job.

Okay, so you've got your iron, and you're ready to rock some DTF transfers! But hold on a sec – not all DTF films are created equal. They're kinda like different types of tape: some are super sticky, some are thin and delicate, and some are made for specific surfaces. Using the wrong film can totally mess up your transfer. You might end up with a design that peels off, cracks, or fades after a few washes. Nobody wants that!

So, before you buy a DTF film, do a little research. Check the instructions to make sure it's a good match for both your fabric and your iron. It's like picking the right tool for the job – the right film will make all the difference in the world!

2. Test Run: Practice Makes Perfect (Transfers)

Before you press that amazing design onto your favorite shirt, do a test run on a scrap piece of fabric. This lets you fine-tune your iron's temperature and pressure, ensuring a flawless transfer on the real deal. It's like a dress rehearsal for your DTF masterpiece, allowing you to iron out any wrinkles (pun intended!) before the big show.

3. Clean Machine: A Happy Iron Makes Happy Transfers

Just like any well-loved tool, your DTF iron needs a little TLC to keep it performing at its best. Over time, residue from the transfer film's adhesive can build up on the soleplate. This buildup can affect heat distribution and even transfer unwanted marks to your garments.

To keep your iron happy and your transfers looking their best, regularly clean the soleplate according to the manufacturer's instructions. A clean iron is a happy iron, and a happy iron makes for happy transfers!

DTF Regular Iron: Your Budget-Friendly Printing Powerhouse

Want to create awesome custom designs without breaking the bank? Then your regular iron is about to become your new best friend! Seriously, this everyday household hero can unlock a whole world of DTF magic.

Think of it like this: your iron is a secret weapon for creating pro-level DTF prints. You can use it to transfer amazing designs onto all sorts of things, from t-shirts and tote bags to hats and even home decor!

The trick is to pick an iron with a few key features: adjustable temperature settings (so you can get the heat just right), even heat distribution (no more hot spots!), and a steam function (for wrinkle-free fabrics). With these superpowers, your iron will be churning out flawless DTF transfers in no time.

DTFPrintDC: Your Resource for Printing Expertise

Want to learn more about DTF printing and stay up-to-date on the latest trends and techniques? Be sure to check out the news section on DTFPrintDC.

Want to become a DTF pro? We've got you covered! Our blog is packed with expert tips, product recommendations, and helpful resources to take your DTF game to the next level.

Think of it as your DTF cheat sheet! We've got everything from troubleshooting guides (for when things go a little wonky) to inspiring project ideas (to spark your creativity).

So, what are you waiting for? Dive in, explore, and unleash your inner DTF master!