Troubleshooting DTF Transfers: Common Problems and Solutions

Hey there, fellow creators! Ever since Direct-to-Film (DTF) printing burst onto the scene, it's totally changed the game for custom apparel. Seriously, the versatility and vibrant colors you can get are just amazing! But let's be real, even with something as awesome as DTF printing, getting those perfect transfers can sometimes be a little tricky. Whether you're a total newbie just starting to explore DTF or a seasoned pro looking to polish your skills, knowing what can go wrong (and how to fix it!) is super important.

That's why we've put together this friendly guide. We're going to dive deep into the DTF transfer process, covering everything from those frustrating smudged inks to the dreaded peeling issues that can sometimes happen. We'll help you troubleshoot common problems, understand why they occur, and give you practical solutions to get those flawless, professional-looking DTF prints you're after. So, if you're ready to take your DTF game to the next level, keep reading! We're here to help you every step of the way.

Understanding the DTF Transfer Process

Okay, before we jump into troubleshooting those pesky DTF problems, let's do a quick recap of the DTF transfer process. It's helpful to have these steps fresh in your mind so you can pinpoint exactly where things might be going wrong. Think of it like retracing your steps when you've lost something – it helps you find it faster!

Here's a simplified breakdown of the DTF process:

-

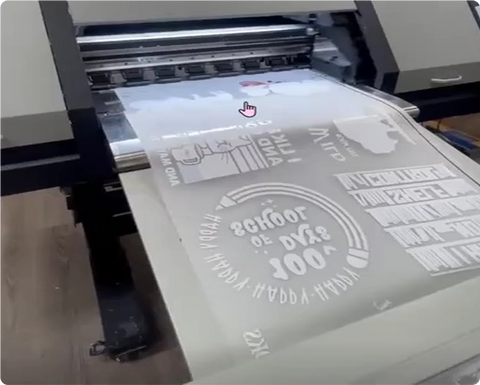

Printing: First, your awesome design gets printed onto a special PET film using those vibrant DTF inks. This is where the magic starts!

-

Powder Power: Next, a heat-activated adhesive powder is sprinkled onto the printed design. This powder is like the glue that will make your design stick to the fabric.

-

Curing Time: Now, the film (covered in that adhesive powder) goes into a heat press or curing oven. This "curing" process melts the powder and gets it ready to bond with the fabric.

-

Transfer Time: The cured film is then pressed onto your fabric using a heat press. This transfers the design from the film to the fabric. It's like magic, but with heat and pressure!

-

Peeling Time: After the fabric cools down a bit, the PET film is peeled off, leaving your beautiful design perfectly adhered to the fabric.

Understanding each of these steps is super important for figuring out where problems might pop up and how to fix them. So, with this process in mind, let's dive into some common DTF issues and their solutions!

Common DTF Transfer Problems and Solutions

Let's tackle some common DTF printing problems and their solutions:

1. Smudged or Blurry Prints – When Your Design Isn't Looking Its Best:

-

Problem: The design on the PET film looks smudged or just isn't sharp. Not the look you're going for!

-

Possible Causes:

- Too much ink.

- Incorrect printer settings.

- The PET film isn't a good match for the ink.

-

How to Fix It:

- Tweak your printer settings to use less ink. Sometimes less is more! Also, make sure you're using the correct resolution for DTF printing.

- Double-check that your PET film is actually designed for DTF printing and is compatible with the brand of ink you're using. They need to play nice together!

- Be patient! Let the printed film dry completely before moving on to the next step. Rushing this can lead to smudging.

2. Uneven Adhesive Powder – Patchy Transfers No More!:

-

Problem: The adhesive powder isn't spread evenly, resulting in patchy transfers. You want a smooth, consistent layer.

-

Possible Causes:

- You might not be applying the adhesive powder evenly.

- The adhesive powder itself might be the problem (quality issues).

-

How to Fix It:

- Gently shake the film while you're applying the adhesive powder. This helps ensure it's distributed evenly. Also, gently remove any extra powder to avoid clumps.

- Think about investing in high-quality adhesive powder. It can make a big difference in getting consistent results.

- Store your adhesive powder in a cool, dry place. This will prevent it from clumping up, which can also lead to uneven application.

3. Designs Not Fully Transferring – When Your Design Stays Stuck on the Film:

-

Problem: After pressing, some parts of your design are still clinging to the PET film instead of transferring completely to the fabric.

-

Possible Causes:

- Your heat press temperature, pressure, or time might be off.

- The fabric might not be prepped correctly.

-

How to Fix It:

- Make sure your heat press is set to the recommended temperature (usually between 160–180°C) and that the pressure is even across the platen. Also, double-check the pressing time – it's usually around 10–15 seconds.

- Preheat your fabric before pressing. This helps get rid of any moisture, which can mess with the transfer process. It's like ironing a shirt before you wear it – it helps smooth things out!

4. Cracking or Fading After Washing – When Your Prints Don't Stand the Test of Time:

-

Problem: Your design starts to crack, peel, or fade after just a few washes. Definitely not what you want! (You can also check out these additional tips [link to tips if you have them]).

-

Possible Causes:

- You might be using low-quality inks or PET films.

- The curing or pressing process might not be quite right.

-

How to Fix It:

- Use high-quality inks and PET films specifically designed for DTF transfers. They're made to last!

- Double-check your curing time and temperature. If you don't cure it enough (under-curing), the design won't stick well. But if you cure it too much (over-curing), you can actually damage the adhesive. It's a delicate balance!

- Give your customers some gentle washing instructions. Suggest washing garments inside out and using cold water. This will help keep their prints looking vibrant for longer.

5. PET Film Sticking to Fabric – When the Film Won't Let Go:

-

Problem: The PET film just won't peel off cleanly, leaving bits of film stuck to the fabric. A sticky situation!

-

Possible Causes:

- The fabric might have been too hot when you tried to peel.

- You might be using the wrong type of PET film.

-

How to Fix It:

- Let the fabric cool down a bit before you try to peel the PET film. Patience is key here! For "cold-peel" films, make sure they've cooled down completely.

- Make sure the PET film you're using is meant for the peeling method you're using (either cold peel or warm peel). They're not all created equal!

6. Uneven or Distorted Design Edges – When Your Design Looks a Little Rough Around the Edges:

-

Problem: The edges of your transferred design look jagged, incomplete, or distorted. Not the crisp, clean look you're after.

-

Possible Causes:

- The film might have shifted during pressing (misalignment).

- The design might not have been trimmed neatly.

-

How to Fix It:

- Before you press, carefully align the PET film on the fabric. You can even use heat-resistant tape to secure it in place so it doesn't move.

- Trim your designs with precision to avoid any rough or uneven edges. A clean cut before pressing is essential for a clean transfer.

Advanced Tips for Optimizing DTF Transfers

-

- Let's talk about some best practices for DTF printing to help you avoid problems in the first place:

1. Gear Up for Success – Using the Right Equipment:

- Printer Power: Invest in a good DTF printer that lets you adjust the settings, especially the ink output. Having control over how much ink is used is crucial for getting the best results.

- Heat Press Hero: A reliable heat press is a must-have. It should distribute pressure evenly for consistent transfers. An uneven heat press can lead to uneven prints.

2. Test, Test, Test – Save Yourself the Trouble:

- Practice Makes Perfect (and Saves Money): Always do a test print on a scrap of fabric before you start a big production run. This will help you catch any potential issues early on.

- Observe and Adjust: Pay close attention to how the test print turns out. If you see anything that's not quite right, adjust your printer or heat press settings until you get the desired result.

3. Maintenance Matters – Keep Your Equipment Happy:

- Clean Printer Heads = Happy Prints: Regularly clean the printer heads to prevent clogs caused by dried ink. Clogged print heads can lead to streaks, missing colors, and other print problems.

- Clean Heat Press = Clean Prints: Keep your heat press clean and free of any debris. Dust, lint, or other gunk on the heat press can transfer onto your fabric and leave unwanted marks.

4. Educate Your Customers – Help Them Keep Their Prints Looking Great:

- Care Instructions are Key: Provide clear washing and care instructions to your customers. This will help ensure the longevity of their garments and keep their prints looking vibrant for longer. A little bit of care goes a long way!

FAQs About Troubleshooting DTF Transfers

Let's tackle some frequently asked questions about DTF printing:

Q1. My DTF printer keeps clogging – what's going on?

Printer clogs are usually caused by dried ink. The best way to prevent this is to use your printer regularly. If you haven't used it in a while, or even if you have, run the printer's built-in cleaning cycles. This will help keep the ink flowing smoothly and prevent those frustrating blockages.

Q2. Can I reuse PET film?

Unfortunately, no. PET films are designed for single use only. Trying to reuse them is likely to lead to poor transfers – the design won't adhere properly, and you'll probably end up with a mess. It's best to use fresh film for each print.

Q3. My prints look dull and faded – how can I fix this?

Dull or faded prints are often a sign of low-quality inks or improper curing. Investing in premium inks will make a huge difference in the vibrancy and longevity of your prints. Also, double-check that you're curing the film properly – both the temperature and the time are important. Too little or too much heat can both cause problems.

The Importance of Troubleshooting Skills in DTF Transfers

Being a DTF troubleshooting pro is a game-changer! It allows you to:

- Reduce Waste: Nobody wants to throw away expensive materials because of a printing mishap. Troubleshooting skills help you identify and fix problems early, minimizing waste and saving you money.

- Save Time and Energy: When issues arise (and they sometimes will!), knowing how to quickly diagnose and solve them saves you valuable time and effort. Instead of spending hours trying to figure things out, you can get back to creating amazing prints.

- Deliver Consistent Quality: Your customers expect high-quality products, every time. Troubleshooting skills enable you to maintain consistent results, ensuring customer satisfaction and building a strong reputation for your brand.

With a little practice and the right knowledge, you'll be able to tackle these challenges head-on and create flawless DTF designs that you're proud of. Don't be afraid to experiment, learn from your mistakes, and keep honing your troubleshooting skills. It's an investment that will definitely pay off!

Problems with DTF Transfers

Let's be honest, even with the best equipment and techniques, challenges can pop up in the DTF transfer process. It's just part of the game. But knowing how to identify the cause of a problem and find the right solution can make all the difference between a frustrating experience and a successful print. From getting that perfectly even adhesive powder application to fine-tuning your heat press settings, every single step in the process plays a crucial role in achieving a flawless result.

By mastering these troubleshooting techniques, you'll not only see a huge improvement in the quality of your DTF transfers, but you'll also build your confidence as a DTF printing professional. Keep experimenting, keep refining your skills, and never stop learning. That's the key to unlocking the full potential of DTF technology and creating truly amazing custom apparel!

Place Your Orders Directly Through Our Website

Ready to bring your custom designs to life? DTF Print DC makes the ordering process super easy and stress-free! You can conveniently place your orders directly through our website. Just browse our services, upload your artwork, and we'll take care of the rest! It's that simple.

At DTF Print DC, we're passionate about delivering top-notch DTF transfers and providing exceptional customer service. Whether you're a business owner looking to create branded merchandise, a hobbyist exploring your creative side, or planning a special project, we're here to help you every step of the way. We're committed to making your custom printing experience smooth, enjoyable, and successful. So, what are you waiting for? Let's get started on your next amazing DTF project!

Get started today by visiting DTF Print DC and experience the easiest way to create your custom apparel.