DTF Printing for Beginners: A Step-by-Step Guide

It is a cool new way to make awesome custom designs. It's super easy to learn, budget-friendly, and perfect for beginners. You don't need any fancy experience for making DTF prints or a ton of money to get started! Plus, your designs will be vibrant and last a long time! This means your creations will look amazing and stay that way wash after wash.

This guide has everything you need to know about it, from the equipment you'll need (like the special printer and magic powder!) to troubleshooting tips to help you avoid common mistakes. We'll walk you through the whole process step-by-step, so you can start creating your own custom DTF transfers masterpieces in no time. Let's get printing!

What Are DTF Prints?

It is a really cool way to get your designs directly onto fabric. Imagine it like this: you print your design onto a special film, then sprinkle it with a magic powder that makes it stick to your fabric like a super strong sticker!

This method is awesome because it works on all sorts of fabrics, like cotton, polyester, and blends. So, whether you're making t-shirts, tote bags, or hats, it gives you amazing, long-lasting designs that won't crack or fade.

What's really cool is that custom transfers is way more versatile than older methods like screen printing. You don't need to create separate screens for each color, and you can print on different types of fabric without any hassle. This makes it a great choice for creating custom apparel and other personalized items, giving you tons of creative freedom!

Why Choose DTF Printing?

It is awesome for anyone starting a custom printing business. It's like having a superpower that lets you create amazing designs with ease! Here's why it's so fantastic:

- No fabric worries: DTF direct to film transfers works on almost any fabric, from cotton and polyester to blends. So, you can print on a huge variety of items without limitations.

- Super durable: Your prints will stay looking great wash after wash. Say goodbye to cracking and fading!

- Affordable to start: You need less equipment compared to other methods like screen printing. This means you can get your business up and running without breaking the bank.

- Amazing quality: Get those bright, sharp colors you want. Your designs will look professional and eye-catching.

- Easy peasy: It is super easy to learn, even for beginners. You'll be creating awesome prints in no time!

With all these benefits, it is a fantastic option for making awesome custom clothes or promotional items. It's the perfect way to unleash your creativity and build a successful business days!

Equipment You’ll Need for DTF Prints

Okay, so you're ready to start your adventure? Awesome! To make it happen, you'll need a few key supplies:

- DTF Printer: This is the heart of your operation! It's a special printer that prints upload your designs onto a film, kind of like a regular printer but specifically designed.

- PET Film: Think of this as the special paper for your printer. It's what your design gets printed on before it's transferred to your fabric.

- Adhesive Powder: This is the magic ingredient! This special powder is what makes your design stick to the fabric like glue.

- Heat Press: This is like a super-powered iron. It uses heat and pressure to transfer your design from the film to your shirt, bag, or whatever you're customizing.

- DTF Inks: These are special inks made just for this. They come in all sorts of colors, plus white, which is important for making your vibrant colors really pop!

- Curing Oven (Optional): This helps set the adhesive powder. Some dtf heat transfer presses have a curing function built-in, so you might not need a separate oven.

Getting good quality tools will make your prints look amazing and make the whole process a lot smoother. It might seem like a bit of an investment upfront, but trust me, it's worth it! Think of it as investing in your success and all the awesome creations you're going to make!

How to Create DTF Prints: Step-by-Step

- Design Preparation

Alright, now it's turnaround time to unleash your inner artist! First things first, you'll need to create your awesome design. There are lots of design programs you can use, like Photoshop or CorelDRAW. If you're new to design, there are also some user-friendly options out there like Canva.

Whatever you use, just make sure your design is super high-quality so it looks sharp and crisp when it's printed in its file format. Think of it like this: you're creating a digital sticker.

One special thing is that you'll need to add a white layer underneath your design. This white layer is like a secret weapon that makes your full color super vibrant. It acts like a base coat, making your design pop off the fabric!

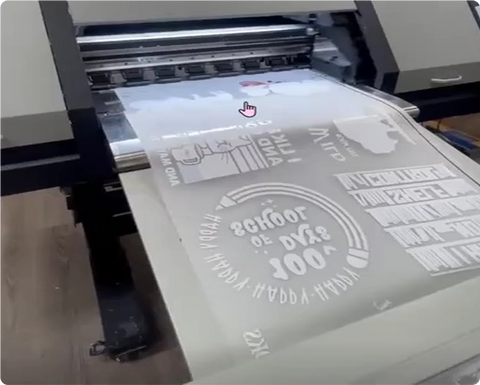

- Printing the Design

Okay, time to get this show on the road! Load your PET film transfer into your printer, just like you would with regular paper in a normal printer. Now, here's the important part: you'll print your design in two steps.

First, your printer will lay down a layer of white ink. This is like the foundation of your design, especially if you're printing on dark fabrics. Think of it as priming the canvas!

Next, the printer will add your design in all its colorful glory using CMYK inks (cyan, magenta, yellow, and black). This is where your creativity shines!

- Applying Adhesive Powder

Alright, now for the fun part! As soon as your design comes out of the printer, it's time to work quickly! While the ink is still wet, you're going to sprinkle a thin layer of that magic adhesive powder all over it. This powder is like the glue that holds your design onto the fabric when you use the heat press.

Think of it like adding sprinkles to a cake, but you want a nice even coating, not a big pile in one spot. Too much powder can make your design clumpy and messy, so shake off any extra. You want a thin, even layer of powder magic!

Powder Curing

Now it's time to melt that magic powder! You can use a special oven called a curing oven, or just your trusty heat press on a low setting. This melts the powder so it sticks evenly to the ink. Think of it like melting cheese onto a pizza - it makes everything come together nicely!

5. Transferring the Design

Okay, you're in the home stretch! Now, take your printed film and carefully place it onto your fabric. Make sure it's lined up exactly how you want it because once it's pressed, it's permanent!

Next, it's time to bring in the big guns: your heat press! This awesome machine is like a giant iron that uses heat and pressure to transfer your design from the film to the fabric.

You'll want to set the temperature to around 160-180°C (that's 320-356°F) and press down firmly for about 10-15 seconds. This will permanently fuse your awesome design to the fabric, making it part of the shirt (or bag, or whatever you're making)!

6. Removing the Film

And now for the moment of truth! Let the fabric cool down for a few seconds – this is important so you don't burn yourself and to give the adhesive time to set properly. Then, slowly and carefully peel off the film.

Ta-da! Just like magic (but actually science!), your amazing design should now be perfectly printed on the fabric.

Congratulations! You've officially created your first masterpiece. Pretty cool, right? Now you can show it off to the world.

Common Mistakes to Avoid

Okay, so you're excited to start pressing DTF transfers, but you're a little worried about messing things up? Totally understandable! Even though it is pretty easy to learn, there are a few common mistakes that beginners sometimes make. But don't worry, we've got your back! These tips will help you avoid those pitfalls and become a pro in no time:

-

Powder problems: Remember that magic adhesive powder we talked about? It's super important to shake off any extra powder after you sprinkle it on your design. Think of it like adding sprinkles to a cake – you want a nice even layer, not a big pile in one spot. Too much powder can make your design clumpy and messy, so give it a good shake to get rid of any excess. This will help your design stick to the fabric evenly and smoothly.

-

Smudgy situations: Before you add that magic powder, make absolutely sure the ink on your design is completely dry. It's like waiting for paint to dry before you touch it – if you rush it, you'll end up with a smudged mess! If the ink is still wet when you add the powder, it can smear and ruin your design. So, be patient and let that ink dry completely!

-

Heat press heroics: Always double-check that you're using the right temperature on your heat press. Each type of fabric and film might have different ideal temperature settings. If you crank up the heat too high, you could end up scorching your design or even the fabric itself. Ouch! So, be sure to consult the instructions and find that sweet spot for the perfect temperature.

With a little practice and by keeping these tips in mind, you'll be creating amazing things in no time! Don't be afraid to experiment and have fun with it. The more you practice, the more confident you'll become.

By tackling these common issues early on, you'll be able to improve the quality of your prints and become a true master!

You want to learn more detailed information about the best way to cut out images for DTF prints, you can also check this blog.

Comparison with Other Printing Methods

To understand why it is ideal for beginners, it’s helpful to compare it with other methods:

|

Feature |

DTF Prints |

Screen Printing |

Heat Transfer Vinyl |

|

Fabric Compatibility |

Almost all fabrics |

Limited |

Limited |

|

Setup Cost |

Moderate |

High |

Low |

|

Print Durability |

Excellent |

Excellent |

Moderate |

|

Complexity |

Low |

High |

Moderate |

It excels in versatility and ease of use, making it a favorite for both beginners and professionals.

Tips for Success

You're well on your way to becoming a master! But here are a few extra tips to help you really level up your skills:

-

Keep things tidy: Just like your mom always said, "Cleanliness is next to godliness!" Okay, maybe she didn't say that about DTF printers, but it's still true. A clean printer is a happy printer, and regular cleaning will prevent clogs and keep your prints looking their best.

-

Quality over quantity: When it comes to DTF supplies, quality really matters. Using good PET film and adhesive powder will make a big difference in the durability and vibrancy of your prints. Think of it as investing in your success!

-

Be a mad scientist (but in a good way!): Don't be afraid to experiment with different settings on your heat press. Different fabrics might need different temperatures and pressing times to achieve the perfect result. Keep track of what works best for different materials, and soon you'll be a wizard!

-

Practice, practice, practice: The more you print, the better you'll get. So keep experimenting, keep creating, and most importantly, keep having fun!

With these tips and a little practice, you'll be creating amazing prints that will wow everyone.

Applications of DTF Prints

It is like a superpower that lets you put your designs on tons of different things, not just clothes! It's your chance to unleash your inner artist and customize the world around you. Think of it like having a magic wand that can instantly transform ordinary objects into personalized works of art!

Need some inspiration? Here are a few ideas to get your imagination flowing:

-

T-shirts: This one's a classic for a reason! Make awesome shirts for your business, a special event, a family reunion, or just for fun! You can create unique designs that express your personality, promote your brand, or celebrate a special occasion. The possibilities are endless!

-

Bags: Decorate tote bags or backpacks with your own designs, quotes, or artwork. It's a great way to show off your style and help the environment by using reusable bags. Plus, who doesn't love a custom bag that's totally unique and reflects their personality?

-

Sports gear: Add your team logo or name to jerseys, hats, water bottles, and other sports items. Show your team spirit with personalized gear that will make you stand out from the crowd. Imagine your whole team sporting custom-designed jerseys with their names and numbers – you'll be the envy of the league!

-

Home décor: Spruce up your home with custom pillowcases, wall art, canvas prints, and more. It gives you the power to personalize your space and make it truly your own. Create a gallery wall with your favorite photos, design a statement pillow with an inspirational quote, or add a touch of whimsy with custom-printed curtains.

But don't stop there! Really, you can use your printing on almost anything you can imagine! Phone cases, mousepads, hats, shoes, even your laptop cover – the possibilities are endless. Get creative, think outside the box, and see what awesome things you can come up with. The world is your canvas!

The Future: What's Next?

The world of DTF printing is constantly evolving, kind of like a cool video game that keeps getting better with new updates! New printers, inks, and materials are being developed all the time, making the process even easier and the results even more amazing. It's an exciting time to be a part of the revolution!

Here are a few trends and advancements to keep an eye on:

1. Eco-Friendly Innovations

Sustainability is becoming increasingly important, and the this industry is taking notice. Many manufacturers are developing eco-friendly inks and films that have a lower environmental impact. You can expect to see more sustainable options hitting the market, making it easier for you to create awesome prints while being kind to the planet.

2. Faster and More Efficient Printers

Just like your favorite video game console gets faster and more powerful with each new generation, DTF printers are also becoming more efficient. New models are being developed that can print faster and with even higher resolution, allowing you to create stunning prints with incredible detail in less time.

3. New and Exciting Materials

Get ready for a whole new world of possibilities! Researchers are constantly experimenting with new materials that can be used. This means you might soon be able to print your designs on even more surfaces, from different types of fabrics to unique materials like wood or metal. Imagine the possibilities!

4. Integrated Workflow Solutions

The future is all about streamlining the process and making it even easier for you to create amazing products. Expect to see more integrated workflow solutions that combine design software, printer management tools, and even e-commerce platforms, all in one place. This will make it easier than ever to manage your printing business and create custom products from start to finish.

Taking Your DTF Printing to the Next Level

Okay, so you've got the basics, and you're ready to take your skills to the next level? Awesome! Here are some expert tips to help you become a true pro:

-

Fabric Fun: It works great on cotton and polyester, but don't be afraid to try it out on other materials like denim, leather, or even silk! Each fabric might need slightly different settings on your heat press, so experiment and keep track of what works best. It's like being a fashion designer, but with a super cool printing superpower!

-

Dazzle with Special Effects: Want to make your designs really pop? Try using metallic, glow-in-the-dark, or glitter DTF films. These special materials can add a unique touch to your prints and make them stand out from the crowd. It's like adding sprinkles and sparkles to your creations!

-

Keep it Cozy: To keep your supplies in tip-top shape, store them in a cool, dry place. Humidity and extreme temperatures can mess with your film, ink, and powder, causing printing problems. Proper storage is like giving your supplies a cozy blanket – it keeps them happy and performing at their best!

-

Bulk Up Your Printing: If you're running a business, printing in bulk can save you tons of time and effort. Instead of printing one design at a time, try prepping multiple prints in advance and pressing them in batches. It's like baking a whole tray of cookies at once instead of one at a time – way more efficient!

-

Automation is Your Friend: As your business grows, think about investing in some automation tools. A shaker and curing system can automatically apply and cure the adhesive powder for you, saving you tons of time and effort. It's like having a robot assistant to help you!

With these tips and a little practice, you'll be creating amazing DTF transfers ready that will wow everyone. So, go out there, experiment, and have fun!

The Business Potential

It isn't just a fun hobby – it's also a fantastic way to make money! With low startup costs and the ability to create high-quality custom products, lots of people are using them to launch successful businesses. Here are a few ideas to get your entrepreneurial gears turning:

-

Custom T-Shirt Printing: Everyone loves a custom tee! Create personalized t-shirts for businesses, sports teams, schools, events, or anyone who wants to show off their unique style. You can even offer on-demand printing services for ordering DTF custom shirts online.

-

Brand Merchandising: Help influencers, small businesses, and startups launch their own apparel lines. Design and print custom t-shirts, hoodies, hats, and other merchandise with their logos and branding. It's a great way to help others build their brands while growing your own business.

-

Etsy & Online Stores: Sell your unique designs on popular platforms like Etsy, Shopify, and Amazon. Create your own online store and showcase your creative talents to the world! You can sell everything from custom t-shirts and tote bags to phone cases and personalized gifts.

-

Corporate Branding: Offer branded uniforms, tote bags, and accessories for companies. Help businesses create a professional and consistent look with custom-printed apparel and promotional items. This is a great way to tap into the corporate market and secure larger orders.

By building a strong portfolio of your work and marketing your services effectively, you can turn your passion into a thriving business. So, unleash your creativity, put on your entrepreneurial hat, and start building your empire!

Advanced Techniques in DTF Printing: Elevating Your Custom Apparel Game

So, you've got the basics of Direct-to-Film (DTF) printing down – awesome! Now, let's explore some cool tricks to make your custom apparel really shine. These tips will not only boost the quality of your stuff but also help your designs stand out from the crowd.

1. Getting Your Colors Just Right

Making sure your colors are spot-on is super important in DTF printing. Good color management means your designs will look exactly how you want them, no matter what you print them on.

- Keep Your Gear Tuned Up: Regularly calibrating your printer and monitor is like giving them a tune-up. It makes sure the colors you see on your screen are the same as what comes out on the print.

- Use ICC Profiles (Don't worry, it's not as complicated as it sounds!): Think of ICC profiles as translators for color. They help make sure colors look consistent across different devices and materials. Using the right profile for your printer and what you're printing on (like a t-shirt or hoodie) can make a huge difference in color accuracy.

2. Making Your Artwork DTF-Ready

Your final print will only look as good as the artwork you start with. So, let's make sure your designs are prepped for greatness!

- Sharp Images are Key: Make sure your designs are created or scanned at a high resolution (300 DPI or higher). This will prevent your prints from looking blurry or pixelated. Think of it like zooming in on a photo – you want it to stay sharp, not get all blocky.

- See-Through Backgrounds: When you have detailed designs or logos, especially ones with complex shapes, save them with a transparent background. This avoids any unwanted borders around your print. It's like cutting out a picture neatly so you don't have any white edges showing.

- Color Modes (A Little Technical, But Important): While you're designing, you can work in RGB mode (that's what most design software uses). But before you actually print, switch to CMYK mode. This is because most printers use CMYK, and it'll help your colors come out looking their best.

3. Pro Heat Press Tips

The heat press is a really important part of DTF printing. Getting your technique down can mean the difference between a good print and a great print – one that really sticks and lasts.

- Pressure is Key: You'll need to adjust the pressure on your heat press depending on what fabric you're using. Too much pressure can make the design bleed or blur, while too little pressure might mean it doesn't stick well. It's all about finding that sweet spot!

- Hot or Cold Peel? After pressing, you'll need to peel off the transfer film. Some materials work better with a "hot peel" (peeling right away), while others do better with a "cold peel" (letting it cool down first). Try both to see what works best for your specific materials. It's like peeling a sticker – sometimes it's easier to peel right away, and sometimes it's better to wait a bit.

5. Keeping Your Gear in Tip-Top Shape

Just like any piece of equipment, your printer needs a little TLC to keep it running smoothly and producing top-notch prints. Regular maintenance will help it last longer and avoid problems down the road.

- Clean Machines = Happy Prints: Make sure you regularly clean the print heads and rollers. This prevents ink from building up and causing streaks or other print issues. Think of it like keeping your brushes clean when you're painting – it makes a big difference!

- Stay Up-to-Date: Don't forget to regularly update your printer's firmware and your design software. These updates often include new features, improvements, and bug fixes that can make your life easier and your prints better.

- Practice Makes Perfect (and Saves Money!): Before you start a big production run, it's always a good idea to do some test prints on fabric scraps. This allows you to catch any potential problems and fix them before you waste a bunch of materials and time. It's like doing a practice run before a big game.

6. Printing with the Planet in Mind

These days, everyone's thinking more about the environment. Using sustainable practices in your DTF printing business isn't just good for the planet – it can also make your brand look even better.

- Eco-Friendly Inks: Choosing water-based or non-toxic inks is a great way to reduce your impact on the environment. These inks are generally better for the planet and for people.

- Energy Smart: Think about using energy-efficient equipment. Things like your heat press and printers can use a lot of power, so choosing energy-saving models can make a difference.

- Reduce, Reuse, Recycle: Try to minimize waste as much as possible. For example, you can optimize your designs to use less film, and look for ways to recycle leftover materials.

By using these advanced techniques, you can create amazing custom apparel that not only meets but blows away customer expectations. In the world of custom printing, things are always changing, so it's important to keep learning and adapting. This will help you stay ahead of the curve and make sure your creations are always top-notch and innovative.

Your Creative Adventure Starts Now!

That's one of the coolest things about this: it's super beginner-friendly, but it also has the power to create professional-quality designs that will last. This guide has equipped you with all the basics you need to embark on your journey, so now it's time to let your imagination run wild!

It is like unlocking a treasure chest of creative possibilities! Whether you're designing for yourself, your friends, or your customers, the only limit is your imagination. With practice, experimentation, and attention to detail, you can hone your skills and create stunning, long-lasting prints that will wow everyone.

So, what are you waiting for? It's time to take action! Fire up your DTF printer, gather your supplies, and let your creativity run wild. Don't be afraid to experiment, try new things, and most importantly, have fun with the process! The world of DTF prints is waiting for you – go out there and make your mark!

Whether you're dreaming up personalized gifts for friends and family or launching a full-fledged custom printing business, it gives you the power to bring your ideas to life. So go out there, experiment, have fun, and create some amazing things!