DTF Transfers vs. Traditional Screen Printing: Which is Right for You?

When it comes to garment customization, finding the right printing method is crucial. Two popular options, DTF transfers and traditional screen printing, often top the list for apparel decorators. Both methods offer unique benefits and challenges, but which one fits your specific needs? In this guide, we’ll dive deep into the details, comparing these methods on cost, durability, versatility, and more. By the end, you’ll be equipped to make an informed decision.

Understanding DTF Transfers

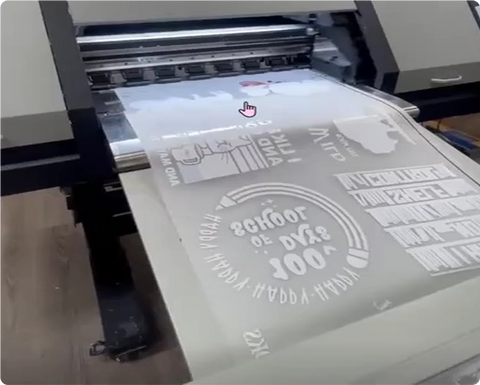

DTF transfers are a modern printing process in which a design gets onto fabric with the help of a particular film. In the DTF technique, ink is printed on the film first, then the powdered adhesive is applied over it, and after curing the print, it is transferred to fabric using heat.

Key Features of DTF Transfers

- Material Compatibility: Works on a wide range of fabrics, including cotton, polyester, blends, and even non-traditional materials like nylon and leather.

- Detailed Printing: Handles intricate designs, gradients, and vibrant colors with ease.

- Low Order Minimums: Ideal for small runs or even single-item projects.

- Durability: DTF prints are highly resistant to cracking, peeling, and fading, even after multiple washes.

Drawbacks of DTF Transfers

- Costly Setup: Initial equipment costs can be high, including the specialized printer, adhesive powder, and heat press.

- Time-Intensive for Large Orders: While great for small batches, the process can be slower for bulk production compared to screen printing.

What Is Traditional Screen Printing?

Screen printing, one of the oldest garment printing methods, involves creating stencils (screens) for each design layer. Ink is pushed through these screens onto the fabric, layer by layer. This method is renowned for its efficiency in bulk orders and its vibrant, long-lasting prints.

Key Features of Screen Printing

- Cost-Effective for Bulk Orders: Once the screens are prepared, the cost per item decreases significantly with volume.

- Durable Prints: Ink bonds deeply with the fabric, resulting in long-lasting and vibrant designs.

- Ideal for Simple Graphics: Bold, single-color designs or logos shine with screen printing.

Drawbacks of Screen Printing

- Limited Material Options: Works best on flat, smooth fabrics like cotton or polyester.

- Complex Setup for Small Runs: High setup costs make small orders less economical.

- Design Limitations: Struggles with intricate patterns, gradients, or highly detailed artwork.

DTF Transfers vs. Screen Printing: A Detailed Comparison

1. Material Compatibility

- DTF Transfers: Perfect for a variety of materials, including tricky surfaces like nylon, leather, and spandex. You

- Screen Printing: Best for flat, smooth fabrics and struggles with complex textures.

2. Design Flexibility

- DTF Transfers: Can handle detailed, multicolored designs with gradients and fine lines.

- Screen Printing: Excels in simple, bold designs with a limited number of colors.

3. Order Volume

- DTF Transfers: Designed for short runs and personalized projects.

- Screen Printing: More efficient and cost-effective for large-scale orders.

4. Durability

- DTF Transfers: High durability, with designs resisting cracks and fading even after frequent washing.

- Screen Printing: Also durable, but heavy washing over time may cause minor cracking or fading.

5. Cost Considerations

- DTF Transfers: Higher initial costs for equipment, but no significant setup costs make it ideal for small projects.

- Screen Printing: Low cost per item in bulk, but high upfront setup costs make small orders expensive.

6. Environmental Impact

- DTF Transfers: Produces minimal waste but requires specialized films and powders.

- Screen Printing: Can use eco-friendly inks, but the process generates waste from screens and excess ink.

You can also check this blog in our website.

When to Choose DTF Transfers

DTF transfers are ideal for:

- Small Batch Orders: If you need fewer items or even a single print, DTF is cost-effective.

- Complex Designs: Detailed artwork or multicolored images are reproduced accurately.

- Versatility: Perfect for non-traditional fabrics like nylon or leather.

- On-Demand Printing: Ideal for e-commerce businesses offering customized apparel.

Examples of DTF Applications:

- Custom t-shirts with vibrant, multicolored graphics.

- Sports jerseys made from synthetic fabrics.

- Personalized tote bags, hats, and even shoes.

When to Choose Screen Printing

Traditional screen printing works best for:

- Bulk Orders: Large quantities reduce the cost per item significantly.

- Simple Designs: Bold, logo-style graphics in one or two colors.

- Flat Fabrics: Cotton or polyester garments are ideal.

- Cost-Sensitive Projects: If you’re producing hundreds of items, screen printing offers excellent value.

Examples of Screen Printing Applications:

- Company uniforms with a bold logo.

- Event merchandise like t-shirts or hoodies.

- Promotional tote bags with simple graphics.

How to Decide Between DTF Transfers and Screen Printing

To choose the right method, consider these factors:

- Order Size: For small orders, go with DTF. For bulk, screen printing is more economical.

- Design Complexity: Detailed, multicolor designs work best with DTF, while simple designs suit screen printing.

- Fabric Type: If you’re working with non-traditional materials, DTF transfers are the way to go.

- Budget: Consider setup costs, material costs, and per-item costs for each method.

FAQs About DTF Transfers and Screen Printing

1. Are DTF transfers better for custom apparel businesses?

Yes, especially if your business offers one-off or low-volume customizations.

2. Can screen printing handle detailed artwork?

Not effectively. Screen printing is better for bold, simple designs with fewer colors.

3. Which method lasts longer?

Both methods are highly durable, but DTF transfers do a great job of preserving design integrity over time-particularly with tricky fabrics.

4. What are the environmental impacts of each method?

Screen printing can use eco-friendly inks, but it generates more waste. DTF transfers produce less waste but rely on specialized films. You can check these inks.

Tips for Optimizing Your Printing Workflow

No matter which method you choose, these tips will help you achieve the best results:

- Invest in Quality Supplies: Use high-quality inks, films, and fabrics to ensure professional results.

- Test Prints Before Full Runs: Print a sample to verify color accuracy and design placement.

- Maintain Your Equipment: Regular cleaning and maintenance prolong the lifespan of your tools.

- Train Your Team: Ensure your staff understands the nuances of each method to avoid costly mistakes.

Which Printing Method is Right for You?

It basically comes down to your needs. If versatility, detail, and small-batch printing are your top priority, DTF transfers are your go-to choice. On the other hand, traditional screen printing can't be beaten in efficiency or cost if your order is very large and the design is simple.

By understanding the strengths and limitations of each process, you will be able to confidently determine the right printing solution for your project. Whichever method you choose, use quality materials and good technique to achieve superior results each time.

Place Your Orders Directly Through Our Website

At DTF Print DC, we make the ordering process seamless for you. If you're ready to bring your custom designs to life, you can conveniently place your orders directly through our website. Simply browse our services, upload your artwork, and let us handle the rest!

Our team is committed to delivering high-quality DTF transfers and outstanding customer service. Whether you're a business owner, a hobbyist, or planning a special project, we're here to help.

Get started today by visiting DTF Print DC and experience the easiest way to create your custom apparel.